Employers are being served with Improvement Notices because they had failed to appoint a competent person to thoroughly examine and test their LEV plant.

The Health and Safety executive (HSE) has highlighted its concerns about assessors passing sub-standard LEV systems as fit for purpose and exposing hundreds of people to unacceptable – and unlawful – levels of risk. Several testing companies that had been served improvement notices have been named and shamed and, in each case, action was also taken against the employer responsible for the equipment as well.

As we always say about all the essential services we offer, the buck stops with the person responsible for operating the building, be it the owner or occupier. You rely on specialist engineers to advise you of faults and dangers, so it is vital to choose your service provider wisely and to challenge them to prove that they are competent.

You need to know that they understand the law and what qualifications and standards the individuals who work at your premises should have. If in any doubt, ask.

What is the law on LEV testing?

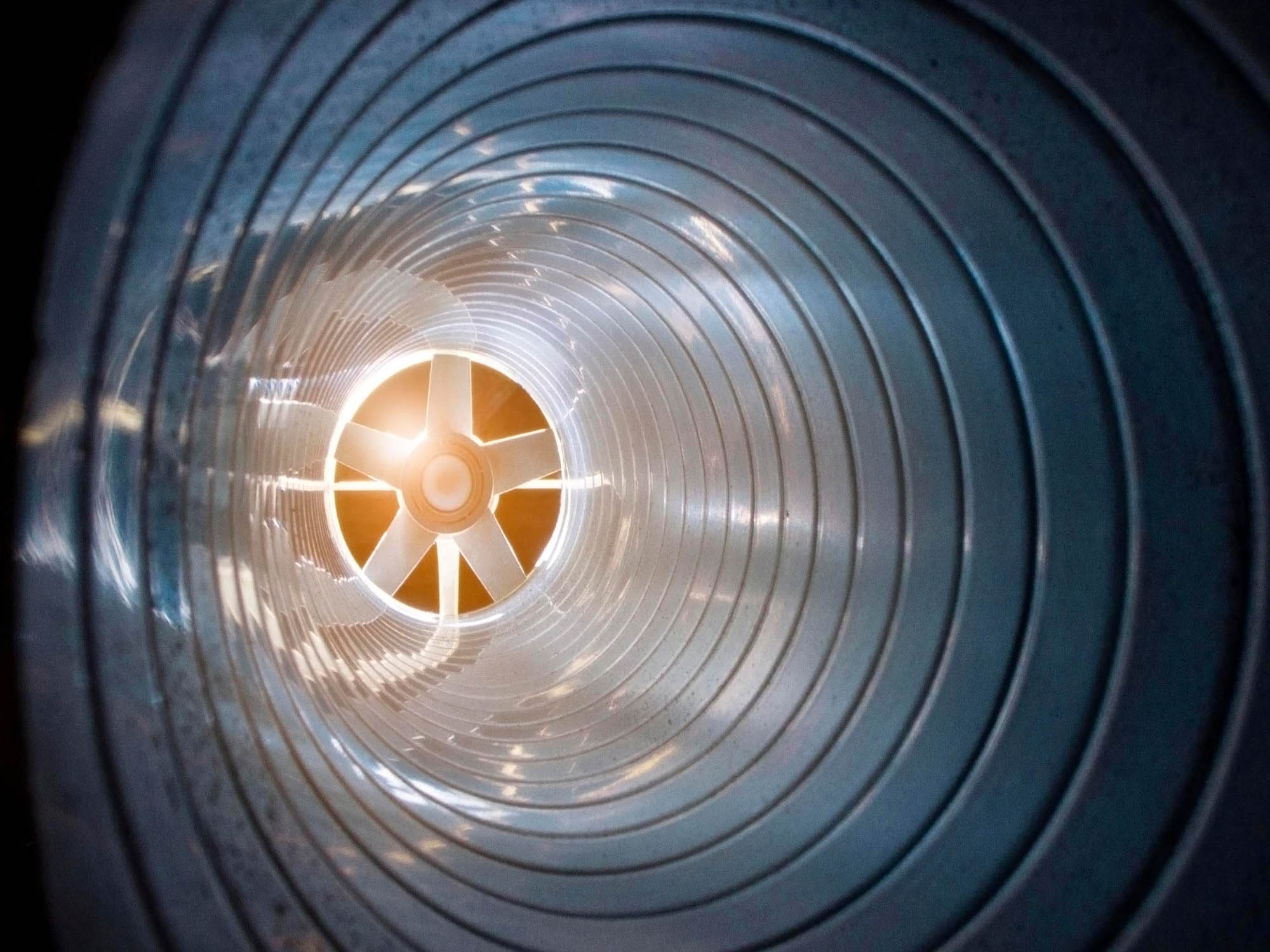

A workplace that uses any kind of process which creates harmful airborne contaminants including dust, oil mist, welding fumes, smoke and vapours will require Local Exhaust Ventilation (LEV) that removes the contaminants from the air before they can be breathed in. Capture hoods are probably the probably most common form of LEV.

The COSHH Control of Substances Hazardous to Health regulations tell you what you need to do. The Health & Safety Executive’s HSG258 Controlling airborne contaminants at work: A guide to local exhaust ventilation (LEV) guides you on how to do so.

The law calls for regular LEV testing, at least every 14 months by a competent person. Do your contractors have your back?

What you have to do

COSHH is the law that requires employers to control exposure to materials in the workplace that cause ill health.

You can prevent or reduce workers exposure to hazardous substances through:- risk assessment,

- control,

- management,

- maintenance,

- training,

- monitoring,

- planning for emergencies, and

- planning for emergencies.

How to do keep your LEV systems safe?

To keep LEV systems working efficiently and prevent exposure to hazardous fumes and dust, LEVs need to be regularly examined and tested by a competent person, at least every 14 months, as defined in HSE document HSG258.

Testing involves thorough visual and structural examination and testing (often abbreviated as TExT). HSG258 says it must be done by a competent person and must include checking the air flow to make sure that the system is adequately removing contaminants from the air. You must keep proof that your LEV system has been tested and passed on file for a minimum of 5 years.

Who can test LEV systems?

What is competency in LEV TExT? The recognised qualifications are the British Occupational Hygiene Society’s (BOHS P601 Examination and Testing of LEV Systems. You also should expect your service provider to have that have good knowledge of systems design which is certified by the P602 Basic Design Principles of Local Exhaust Ventilation Systems qualification.

BOHS has been the only organisation dedicated to occupational hygiene. It holds a Royal Charter and sets the standard for LEV testing and maintenance competency.

At Airmec we regularly inspect and test LEVs in various locations and can advise on and undertake remedial works required.

What can go wrong with LEV?

Problems reported by the Health and Safety Executive include:- the capture zone does not cover the whole working zone,

- inadequate air flows (i.e. reduced or no detectable airflow),

- badly damaged ducting and hoods,

- blocked ductwork, and

- damaged or missing filters.

Of course, there is also the risk of bad practice and people not really appreciating the risks. Why not make sure everyone working in contaminated areas has a copy of this pocket guide.

Find out more about Airmec’s ventilation hygiene and air quality services here.

Published: 2 October 2023 | Updated: 27 March 2024