Airmec Essential Services provides consultancy, inspection and ventilation hygiene maintenance services, including comprehensive ventilation system condition surveys and subsequent duct cleaning. We can advise on all ventilation systems and air quality requirements.

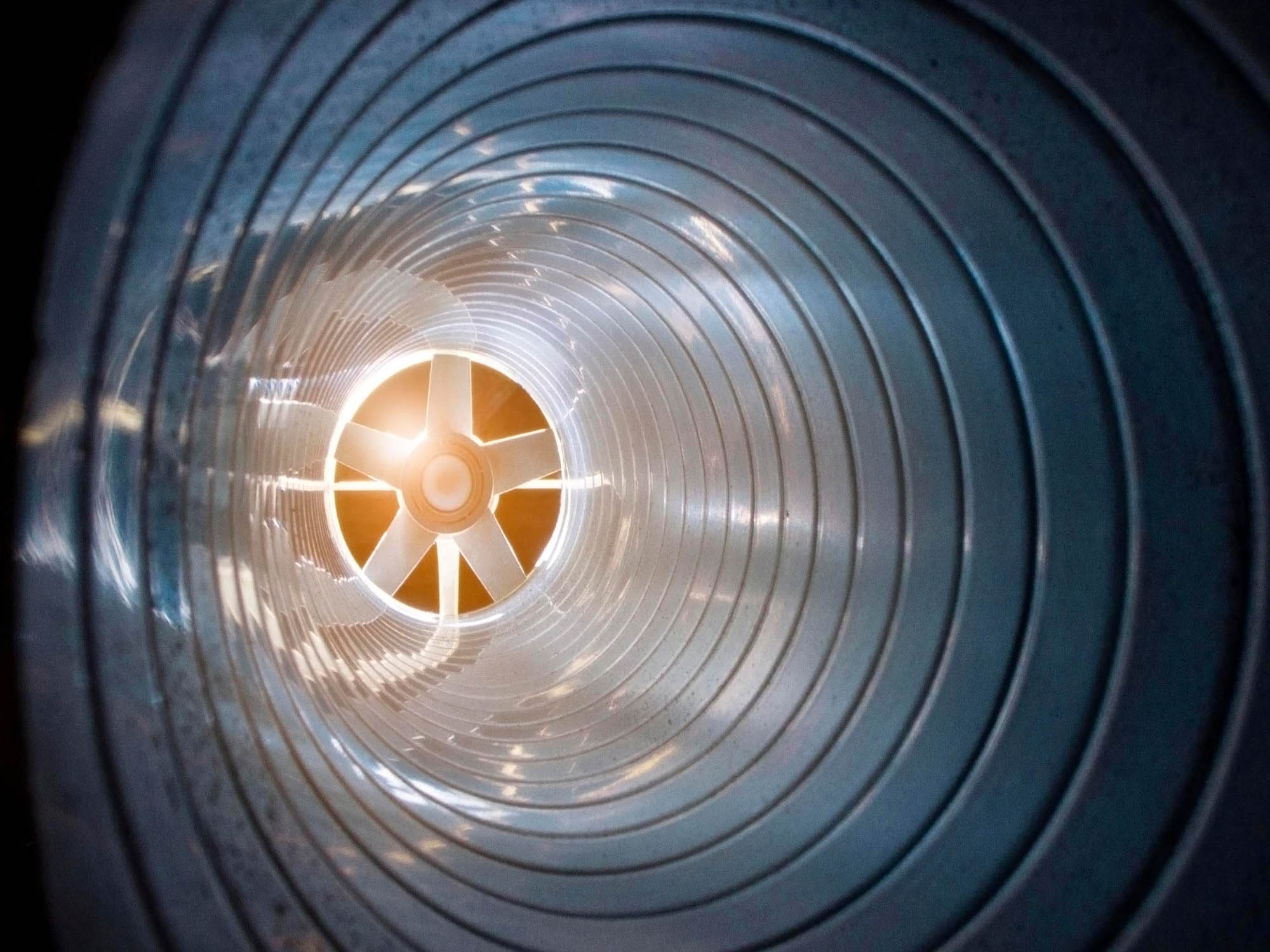

The cleanliness and quality of the air running through a building’s ventilation ducts has a major impact on the productivity of staff, operational costs, and on managing fire risk. Regular duct cleaning is key to maintaining system hygiene and safety, and we offer specialist expertise in scoping and undertaking that work for you.

We are members of the Building Engineering Services Association (BESA) and are approved Ventilation Hygiene Register (VHR) contractors, giving you assurance of compliance and cleaning to TR19® Air and TR19 Grease® standards.

Pre-planned maintenance and duct cleaning regimes should be in place to ensure safe and effective operation of ventilation systems. This should include inspection on a regular basis. The frequency of ventilation duct inspection is tyically determined by the system’s location and function.

Specific industry guidelines govern what cleaning and maintenance must be undertaken to comply with air hygiene guidance, and we can advise accordingly.

After cleaning, we issue detailed reports detailing the ventilation systems cleaned and the results that have been achieved. The report will also outline recommendations on improvements to the maintenance regime, depending on the requirements for your sector.

Airmec will align its recommendations and reports with with your SFG20 schedules.